Inventory Sync Job Monitoring for E-commerce

Inventory accuracy is foundational to e-commerce. When sync jobs fail, consequences are immediate: overselling, false stockouts, frustrated customers.

Inventory Sync Job Monitoring for E-commerce

Inventory accuracy is foundational to e-commerce operations. When inventory sync jobs fail, the consequences are immediate: overselling products you do not have, showing items as out of stock when they are available, and frustrated customers on both ends. This guide provides a deep dive into monitoring inventory synchronization jobs, the systems that keep your stock levels accurate across channels.

Why Inventory Sync Is Critical

Inventory sync jobs carry significant business risk:

Overselling creates unhappy customers: A customer orders a product, receives an order confirmation, and then gets an email saying the item is actually out of stock. They need a refund, they are disappointed, and they may not shop with you again.

Understocking means missed sales: Products show as unavailable when you actually have stock. Customers buy elsewhere. You never know about the sales you lost.

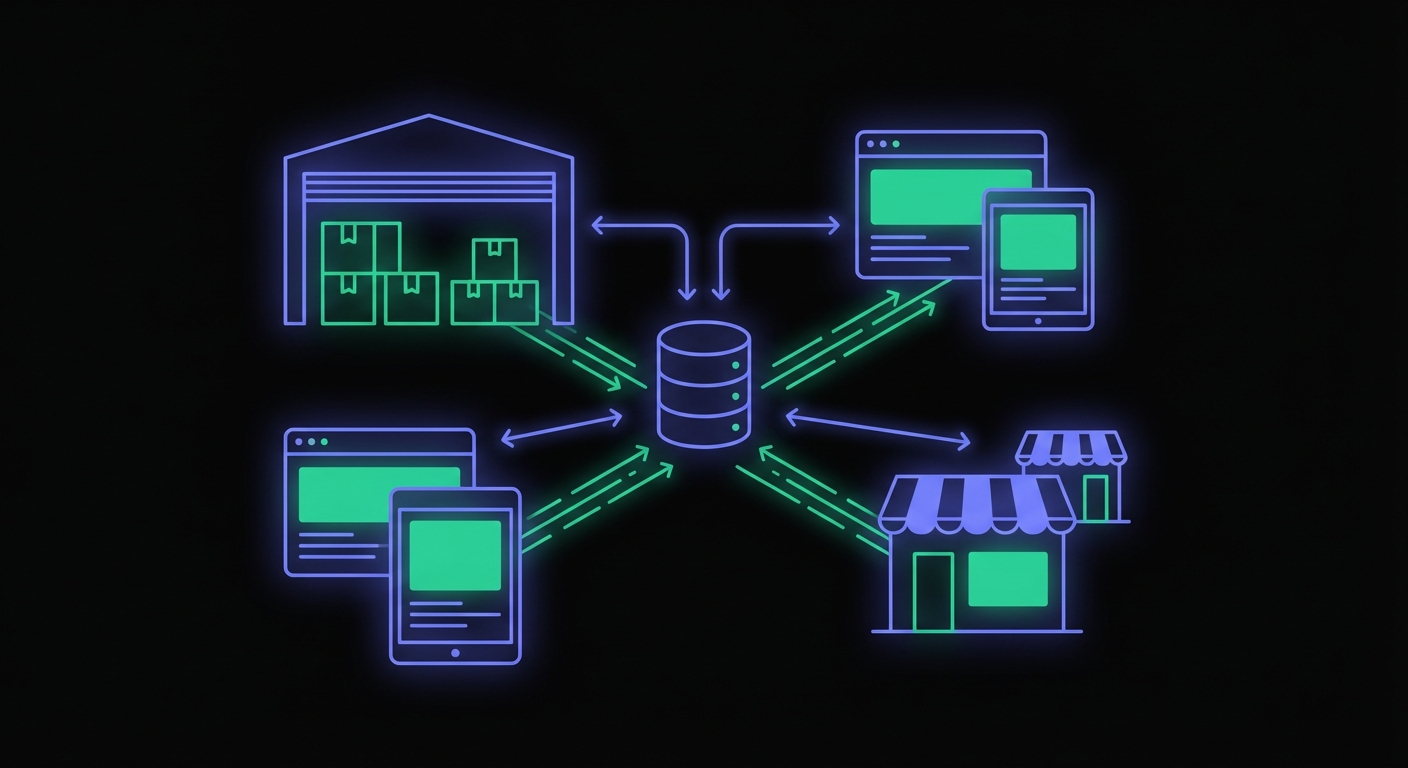

Multi-channel complexity: Modern e-commerce often spans multiple sales channels, your website, Amazon, eBay, retail stores, and wholesale. Inventory must stay synchronized across all of them. For broader coverage of e-commerce scheduled tasks, see our e-commerce cron monitoring guide.

Real-time expectations: Customers expect inventory to be accurate now. A product that shows available should be available when they check out 30 seconds later.

Common Inventory Sync Patterns

Inventory flows between systems in various configurations:

ERP to e-commerce platform: Your enterprise resource planning system is the source of truth. Stock levels sync to your online store.

POS to online store: Retail stores have their own inventory. Sales in-store need to reflect online, and vice versa.

Warehouse to all channels: A central warehouse management system pushes inventory to every sales channel.

Marketplace sync: Sending inventory to Amazon, eBay, Walmart, and other marketplaces. Each has its own API and requirements.

Drop-ship supplier sync: For drop-shipped products, your supplier's inventory becomes your inventory. You need their stock levels reflected in your store.

Each sync direction and destination may require its own job and its own monitoring.

Why Inventory Syncs Fail

Sync jobs fail for reasons specific to integration work:

API rate limits: Marketplace APIs limit how many requests you can make. Hit the limit and your sync stops partway through.

Network timeouts: Syncing thousands of SKUs takes time. Network issues during sync can cause partial updates or complete failures.

Data format changes: The source or destination system changes their data format. Your sync script cannot parse the new format.

Authentication expiration: API tokens, OAuth credentials, or API keys expire. The sync cannot authenticate.

Source system downtime: Your ERP is being upgraded or your supplier's system is down. No source data means no sync.

Each failure mode requires a different response. Monitoring catches the failure. Logs help diagnose the cause. For help selecting a monitoring solution, see our best cron monitoring tools comparison.

Monitoring Inventory Sync Jobs

Here is a comprehensive example of a monitored inventory sync job:

const MONITOR_URL = process.env.INVENTORY_SYNC_MONITOR_URL;

async function syncInventory() {

console.log('Starting inventory sync');

// Signal job start

try {

await fetch(`${MONITOR_URL}/start`);

} catch (e) {

console.error('Monitor start ping failed:', e);

}

try {

// Fetch inventory from source (ERP, WMS, etc.)

const sourceInventory = await erp.getStockLevels();

console.log(`Retrieved ${sourceInventory.length} SKUs from ERP`);

let updated = 0;

let skipped = 0;

let errors = 0;

for (const item of sourceInventory) {

try {

const currentStock = await store.getStockLevel(item.sku);

if (currentStock !== item.quantity) {

await store.updateStockLevel(item.sku, item.quantity);

updated++;

} else {

skipped++;

}

} catch (error) {

console.error(`Failed to sync ${item.sku}:`, error.message);

errors++;

}

}

console.log(`Sync complete: ${updated} updated, ${skipped} unchanged, ${errors} errors`);

// Decide on success/failure based on error rate

if (errors > sourceInventory.length * 0.05) {

// More than 5% errors is a failure

console.error('Error rate too high, signaling failure');

await fetch(`${MONITOR_URL}/fail`);

} else {

await fetch(MONITOR_URL);

}

} catch (error) {

console.error('Inventory sync failed:', error);

try {

await fetch(`${MONITOR_URL}/fail`);

} catch (e) {

console.error('Monitor fail ping failed:', e);

}

throw error;

}

}This example includes error threshold logic. A few SKU failures are acceptable; a significant error rate triggers a failure signal.

Duration Tracking for Syncs

Sync duration provides operational intelligence:

| Duration Change | What It Means |

|---|---|

| Gradual increase | Catalog growing, more SKUs to sync |

| Sudden increase | API performance degradation |

| Sudden decrease | Sync completing early, possible issue |

| High variability | External system performance inconsistent |

A sync that usually takes 5 minutes but suddenly takes 30 minutes warrants investigation. Maybe the source API is slow. Maybe you added many new products. Either way, you want to know.

Duration tracking also helps with capacity planning. If your sync is approaching your job timeout limit, you need to optimize or increase resources before it starts failing.

Multi-Channel Monitoring

When syncing to multiple channels, monitor each separately:

Inventory Monitors

├── erp-to-website (every 15 min)

├── erp-to-amazon (every 30 min)

├── erp-to-ebay (every 30 min)

├── erp-to-walmart (hourly)

└── supplier-to-erp (hourly)

Each channel has different requirements, different APIs, and different failure modes. A problem with Amazon sync should not mask a simultaneous problem with eBay sync.

Separate monitors also allow different alert configurations. Amazon might be higher priority than eBay for your business.

Grace Periods for Inventory

Setting appropriate grace periods requires balancing several factors:

High-velocity items need tight monitoring: Products that sell frequently cannot tolerate long sync delays. A 15-minute grace period might be appropriate.

Slow movers can have longer grace periods: Products that sell once a week can tolerate longer delays. An hour grace period is fine.

Match business tolerance: How long can sync be delayed before it creates real problems? Set grace periods accordingly.

| Product Velocity | Recommended Grace Period |

|---|---|

| Fast movers (>10/day) | 15-30 minutes |

| Regular products | 1 hour |

| Slow movers (<1/week) | 4 hours |

Consider separate monitors with different grace periods for different product categories if velocity varies significantly.

Alert Escalation

Inventory sync failures warrant quick response. Configure escalating alerts:

| Time Since Failure | Action |

|---|---|

| Immediate | Slack notification to #inventory-alerts |

| 15 minutes | Email to operations team |

| 30 minutes | SMS to inventory manager |

| 1 hour | Consider pausing sales (manual decision) |

For high-volume stores, consider automated responses. If inventory sync has been down for an hour, automatically adding a "limited availability" notice to the site protects against overselling.

Reconciliation Monitoring

Beyond regular sync jobs, run periodic full reconciliation:

async function reconcileInventory() {

const MONITOR_URL = process.env.INVENTORY_RECON_MONITOR_URL;

await fetch(`${MONITOR_URL}/start`);

try {

const erpInventory = await erp.getAllStockLevels();

const storeInventory = await store.getAllStockLevels();

let discrepancies = [];

for (const [sku, erpQty] of Object.entries(erpInventory)) {

const storeQty = storeInventory[sku] || 0;

if (erpQty !== storeQty) {

discrepancies.push({

sku,

erp: erpQty,

store: storeQty,

diff: erpQty - storeQty

});

}

}

if (discrepancies.length > 0) {

console.log(`Found ${discrepancies.length} discrepancies`);

await notifyTeam(discrepancies);

// Fix discrepancies

for (const d of discrepancies) {

await store.updateStockLevel(d.sku, d.erp);

}

}

await fetch(MONITOR_URL);

} catch (error) {

await fetch(`${MONITOR_URL}/fail`);

throw error;

}

}Reconciliation catches drift that accumulates over time. Run it daily or weekly depending on your volume.

Handling Sync Failures

When alerts fire, have a response plan:

Immediate assessment:

- Check source system availability

- Check destination API status

- Review error logs for specific failures

Short-term mitigation:

- Can you run a manual sync?

- Should you add buffer stock to prevent overselling?

- Do you need to pause sales on affected items?

Communication:

- Notify customer service about potential issues

- Update internal stakeholders

- Prepare customer communication if needed

Root cause and prevention:

- What caused the failure?

- How can you prevent recurrence?

- Do you need better monitoring or alerting?

Platform-Specific Considerations

Different platforms have different sync challenges:

Shopify: Use the Admin API for inventory updates. Watch for rate limits (40 requests/second at most). Consider bulk operations for large catalogs.

WooCommerce: Updates through REST API or direct database. wp-cron reliability issues affect scheduled syncs.

Amazon: Strict inventory feeds with processing delays. Monitor both submission and processing status.

Marketplace APIs: Each has unique requirements, rate limits, and failure modes. Test thoroughly and monitor closely.

Conclusion

Inventory accuracy depends on sync jobs running reliably. A single missed sync can lead to overselling, customer complaints, and lost revenue. Multiple missed syncs compound into operational chaos.

Monitor every inventory sync job. Track duration to catch performance degradation. Set up separate monitors for each channel. Configure alerts that escalate appropriately for your business.

The investment in inventory sync monitoring pays off immediately. The first time you catch a failed sync before a customer tries to order an out-of-stock item, you have prevented a support ticket, a refund, and a disappointed customer. Small e-commerce businesses should also check our cron monitoring guide for small businesses for budget-conscious strategies.

Cron Crew provides the monitoring infrastructure e-commerce operations need. Create monitors for all your inventory sync jobs, track duration and success rates, and receive immediate alerts when syncs fail. Protect your inventory accuracy by starting your monitoring today.